Project Cost: 10,500

Project Code: 1659

Description of the project:

Nowadays, marketing demands are increasing continuously. If you can’t satisfy demand then you will knock out of the race. There is no time limit for work. So in modern industry, it needs to give alignment without going on the field. Our project “GSM based Industrial Automation” satisfies this need by using a GSM modem by making use of SMS technology.

Consider a case, that you are a field engineer, the company will start at 9 o’clock. But you have to turn on the boiler at 7 o’clock to start working at 9 o’clock. In this case, you have to go at 7 o’clock. But by using this project you can start boiler by just sending an SMS command from your mobile. The boiler is just an example you can turn on or turn off any controlling device by sending SMS.

Now consider another case, you need to monitor various parameters in the industry, say Humidity in a paint shop machine or a critical thing like LPG gas leakage, then you need to be present in the industry/plant. The second part of our project meets this requirement, it monitors the parameters on the LCD and at the same time sends an SMS when these parameters cross the threshold limit.

For controlling the relays, you have to send sms to the GSM modem which you have set on the field. The GSM modem is connected to the Project. This GSM modem will receive your SMS and then that particular relay is turned on/off by reading the sms.

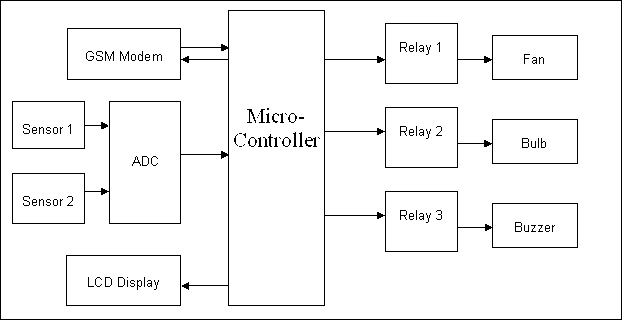

Block Diagram of the GSM based Industrial Automation project:

You will get the following documents with this project:

- Project Report in pdf format as well as in doc (word) format

- You will get a Circuit diagram of the project and the PCB layout of the project

- Microcontroller program in assembly language and Hex file of the microcontroller code

- Datasheets of all the components / ICs used in the project

Project Photographs:

Description in detail:

It mainly consists of the following blocks:

- Microcontroller

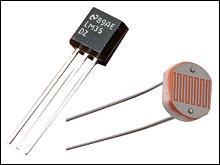

- Humidity or LPG Gas Sensor

- Temperature sensor

- GSM Modem (sim900 unit)

- LCD Display

- The buzzer that beeps for critical conditions

Applications and Advantages of GSM based Industrial Automation:

- We can use this project for Industrial automation as well as for industrial safety purposes.

- It can also be used for security purposes after modification.

- In places where control of action has not any time limit.

- No need to go on the field.

- This project has Higher reliability and also, it is cost-effective.

- Fast and efficient

Future Development for the project:

- We can monitor more parameters & devices as well as we can control these devices in Industrial automation.

- A Voice announcement system can be added to indicate device conditions.

Video of the project: GSM based Industrial Automation

Youtube video coming soon

Questions and answers about this project:

Question: Which type of GSM Modem you have used? Can we use a Mobile instead of a GSM modem?

Answer: We have used SIMCOM300 GSM modem. No, we can not replace GSM modem by Mobile in this project.

Question: What method of communication is being used in this project? Is it by SMS or by phone call? Because I am interested in buying one that uses SMS-based communication.

Answer: This project used SMS communication method. For DTMF based communication, visit this page: www.projectsof8051.com/projects/36-industrial-automation-using-cellphone.html

i lik yor concept this project are use in vry must

I want the project of automatic floor cleaning robot it consist of robotic arm, dc motor,sensors etc…

Hi bala kumar, automatic floor cleaner project is out of stock and it is not available. Please select any other project.

Dear Sir/Madam,

I am interested in GSM BASED INDUSTRIAL AUTOMATION.

I just want to monitor the parameters alone no need to control. For example consider that raw mill runs for 500 Ton per hour, but if it runs below 500 Ton per hour i must get sms.(Like wise i am going to monitor 6 parameters, so i am in need of 6 inputs minimum)

Now regarding sms, to how many numbers sms will be send.

And what text message we will receive.

you are automating power devices like fan, lights or simple small dc devices like leds and dc fans

sir.. tell me the details about home automation project kit cost