Project Cost: 9,100

Project Code: 1240

Description of the project:

Conventional Greenhouse controlling technique or farming techniques does not have a concept of Robotics. This is one of the important projects amongst various agriculture projects for engineering students. This Greenhouse environment controlling Robot project monitors the temperature, humidity, and light inside the greenhouse. And this project controls the temperature and humidity. This unit is installed on a Robot. This robot moves through the greenhouse on a predefined track.

This High technology farming project consists of the below three basic modules.

- Parameters Monitoring

- Parameters Controlling

- The automatic movement of the Robot on a predefined path.

An LCD display unit will show the values of parameters like Temperature, humidity, and Light. This will help the person to know the values, for this purpose we are going to use various sensors, which will be connected to ADC.

The other module is named parameter controlling. It can be used to control the values of temperature. We are going to use two relays for this purpose. The first relay should be connected to a FAN and another should be connected to a heater. This system is useful as many times it’s difficult to measure and control the parameter values manually and also this module is more accurate than the domestic greenhouse system.

The robot is given a predefined motion depending upon the track of the greenhouse. The Robot will move throughout the greenhouse. Then it will measure the values of temperature and light while traveling through the greenhouse. At the same time, it will control the values of these parameters.

PC interfacing is provided so as to send these parameter values to the PC. At the same time microcontroller will send the plant number or the position of the robot to the PC.

Video of the project Autonomous Roving Robot for Greenhouse controlling

Block Diagram of Greenhouse environment controlling Robot:

You will get the following documents with this project:

- Project Report in pdf format and in doc (word) format

- Circuit diagram

- PCB layout

- Microcontroller program in assembly language

- Hex file of the microcontroller code

- Datasheets of all the components / ICs used in the project

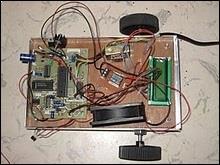

Project Photographs:

A detailed description of the Greenhouse environment controlling Robot:

- TEMPERATURE SENSOR: This is the first sensor which uses to sense temperature. This can be a temperature sensor, say LM35. The sensor will be placed on the front panel. One can use an LCD display to read the temperature.

- LIGHT SENSOR: This is the second sensor which uses to sense light. This can be LDR. The sensor will be placed on the front panel.

- AMPLIFIER: The output voltage of the temperature sensor is in millivolts. But the ADC requires a voltage in the range of 0 to 5 volts. So we need to use an amplifier. We are going to use LM358 which is having 4 inbuilt amplifiers. Since we have two sensors, we have used this Amplifier.

- ADC We are going to use ADC 0808 which is an 8-bit and 8-channel ADC. Since we have two inputs for ADC, we have used this ADC.

- LCD: Liquid Crystal Display which is commonly known as LCD is an Alphanumeric Display which means that it can display Alphabets, Numbers as well as special symbols thus LCD is a user-friendly display device that can be used for displaying various messages, unlike seven segment display which can display only numbers and some of the alphabets. The only disadvantage of LCD over seven segments is that seven segments are a robust display and be visualized from a longer distance as compared to LCD. Here WE have used a 16 x 2 Alphanumeric Display which means on this display WE can display two lines with a maximum of 16 characters in one line.

- MOTOR DRIVER: We need to drive the DC Motors. For this purpose, we need to provide 12 volt supply to the motor. Motor driver IC is used for this purpose. We are going to use L293D as a motor driver IC

- RELAY: We need to control the values of temperature. For this purpose, we need to drive a fan and heater. We are going to use Relay for this purpose

- PC Interfacing: We are going to use MAX 232 for the purpose of PC interfacing, using this module, we can send various data like temperature, and light to the PC.

- MICRO-CONTROLLER (8051): This is the most important segment of the project, i.e. the microcontroller 8052. The controller is responsible for the detection and polling of the peripheral’s status. It is responsible for making. It is responsible for prioritizing all the devices attached to it.

We have used the ATMEL 89s51 microcontroller. The AT89S51 is a low-power, high-performance CMOS 4-bit microcontroller with 8K bytes of in-system programmable Flash memory. It has got 32 I/O lines, a Watchdog timer, two data pointers, two 16-bit timers/counters, six-vector two-level interrupt architecture, a full duplex serial port, an on-chip oscillator, and a clock circuitry.

Applications and Advantages of Greenhouse environment controlling Robot:

- To calculate and control the temperature and light of the environment in the greenhouse.

- The same unit can be used in the industry to control the temperature and light of various units in the industry.

Future Development:

- We can add GSM technology which will send SMS in case any parameter exceeds the higher threshold limit

- We can monitor more parameters of the greenhouse environment

Questions and answers about this project:

Question: What is the size of the Greenhouse Robot?

Answer: Size is approximately 15 inch by 10 inch, actual size may vary.

how will the robot control the parameters?

Can you make a flying bee robot with artificial intelligence.how much does it costs?

What will control the robot, is there any remote?

How does this robot will start and how it’ll operate?? Do we need to code the path every time we change the plants???

Hi Chethan,

When you turn project then Robot start moving forward. Then it stops at 1 plant checks the temperature and humidity.

If it is below threshold value then it moves forward. It does this action for 10 plants and then it moves reverse.

If you change the plant then you have to change the robot movement time in code.

hi can we use line following robot concept here for predetermined way of robot???

Hi manthan , if the path is complicated then we can definitely use that.